How it si done

Prosciutto di San Daniele is made solely with pigs born, bred and slaughtered exclusively in Italy. The breeding methods used respect the well-being of the animal and are subject to constant and thorough checks. The pigs are fed on a controlled diet, specified by the Production Guidelines, based on high quality cereals and milk whey. Thanks to the sea salt and the optimal temperature/humidity/ventilation conditions, Prosciutto di San Daniele can be perfectly preserved without the use of preservatives. The technique and methods used for maturation define the flavour, tenderness and fragrance of the prosciutto.

Selection and trimming

The first test to be passed

On arrival in San Daniele del Friuli, the fresh hams undergo a preliminary conformity check. They are then stored for about 24 hours at a temperature of between -1°C and +3°C to “tone up” the meat. They are subsequently “trimmed” along specific cuts to encourage the loss of moisture and give them their traditional shape.

Salting

One day buried in salt for each kilo of weight

After the first 24 to 48 hours, the hams are covered with sea salt and stored at a temperature of between 0°C and +4°C. Traditionally, the salting time is calculated as a number of days equal to the number of kilograms of weight of each ham. This operation enables the product to be preserved naturally, maintaining its integrity, and improves its flavour.

Pressing

An exclusive stage, typical of San Daniele ham

The hams are pressed uniformly along the muscle mass in order to allow the salt to penetrate in depth and to bring the flesh to the optimum degree of firmness for subsequent maturing. This is a typical stage of the process that is exclusive to San Daniele ham, and is preparatory to providing the conditions for drying the product in the best way.

Rest

In search of a perfect balance

The salted hams are placed to rest in special rooms until the fourth month after the start of the curing process. The humidity in these rooms varies between 70% and 80% and the temperature is kept between +4°C and +6°C. During this stage, the salt penetrates gradually and constantly and is distributed uniformly.

Washing and drying

The ritual ending the cold stage

After resting, the hams are washed with lukewarm water. Washing tones up the flesh and the change in temperature stimulates the start of the maturing processes of the flesh.

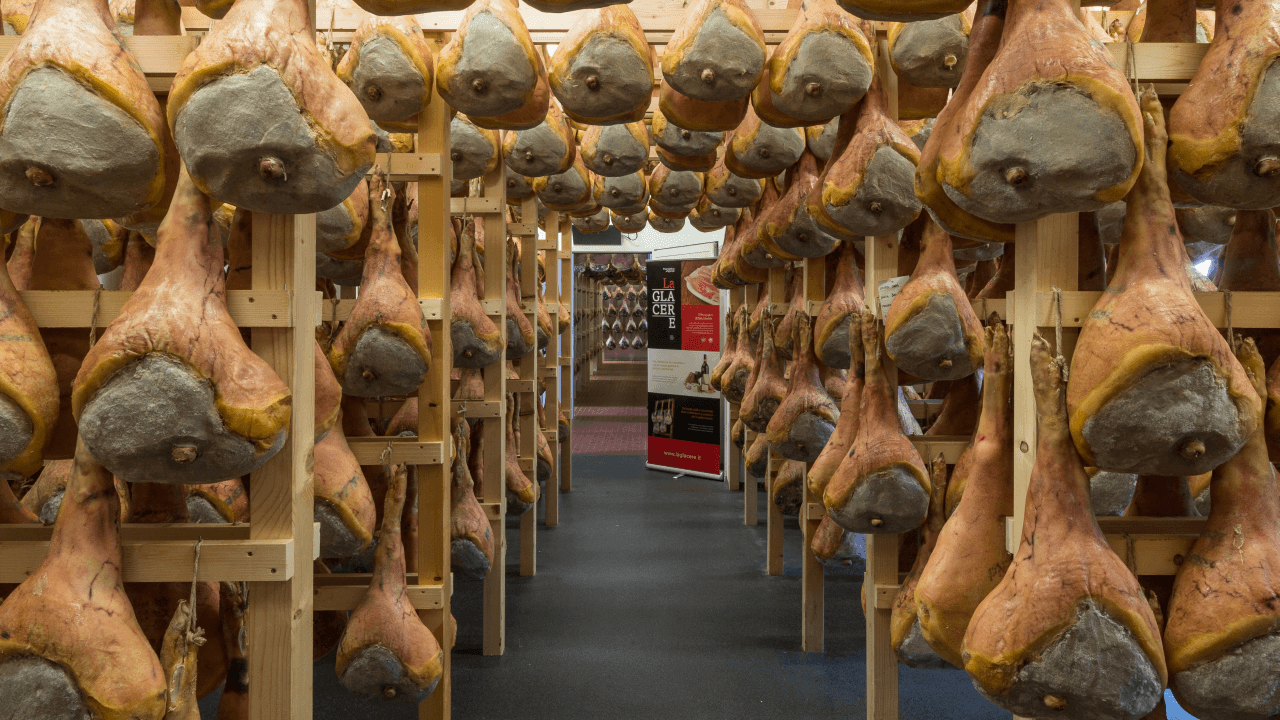

Maturing

In San Daniele this lasts at least 13 months

According to the provisions of the Production Specifications, maturing must last until the end of the thirteenth month after the start of processing. Optimum temperature, humidity and ventilation conditions must be maintained throughout this period.

Smearing with lard

To safeguard its softness

The part not covered by the rind is smeared with “sugna”, a paste consisting of a mixture of lard and rice or wheat flour, in order to protect and simultaneously soften that part of the ham by preventing the underlying flesh from drying out.

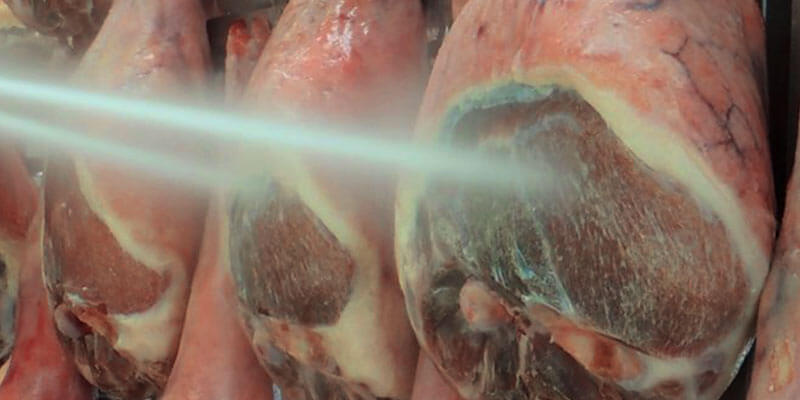

Piercing

Checks during maturing

Inspections are carried out regularly throughout the maturing process. The tests performed include beating, that is to say striking of the ham to monitor its firmness, and piercing with a horse-bone needle in a number of specific spots in order to assess progress of the maturing and the quality of the ham on the basis of its smell.

Branding

Certification by the consortium

Upon completion of the 13th month from the start of processing, the IFCQ Certification Body performs the final inspection of the product. Hams that meet all requirements of the Production Specifications are certified and branded with the mark of the consortium, which includes the producer’s identification code. It confirms the certification and guarantees the quality of the ham.